WATERTECH CHINA 2024

Here is a description of the news details.Here is a description of the news details.

Founded in 1989, Hongteng (WUXI HENGTENG ENVIRONMENTAL TECHNOLOGY CO.,LTD) has been a leading filter cartridge making machine manufacturer in China. We focus on PP melt blown filter cartridge machine, CTO carbon block filter machine, UDF filter machine, and PP yarn winding filter machine. We boast design teams, research center and 6000 square meter factory to deliver high-quality filter cartridge making machine. Based on our good product and careful technical guide, our spun filter making machine has exported to many countries, such as India, Egypt, Iran, Ukraine, France, Brazil, and Turkey.

As a professional spun filter making machine supplier, we have awarded with IS09001, CE and other domestic certification. From design, production, install to after-service service, we can bring you a total solution on filter element production line.

Over more than 35 years of experience, Hongteng has introduced and adopted advanced technology to manufacture high-quality filter cartridge making machine. We specialized in PP melt blown filter making machine, PP String Wound filter and CTO carbon filter making machine, Melt blown fabric making machine and series of extruders.

We stick to supply reliable spun filter manufacturing machine to global market!

Customer First! Reputation Utmost! Producing Better! Good machine!

High Quality

We have advanced production equipment, testing process, and engineer team to ensure high quality spun filter making machine. Before shipping, we will possess strict quality control 5 times to achieve high filtration accuracy. After a series of QC process, our filter cartridge making machine can satisfy your long-term needs. If you are looking for filter cartridge making machine with good filtration ability, Hongteng will be your best partner.

Good Service

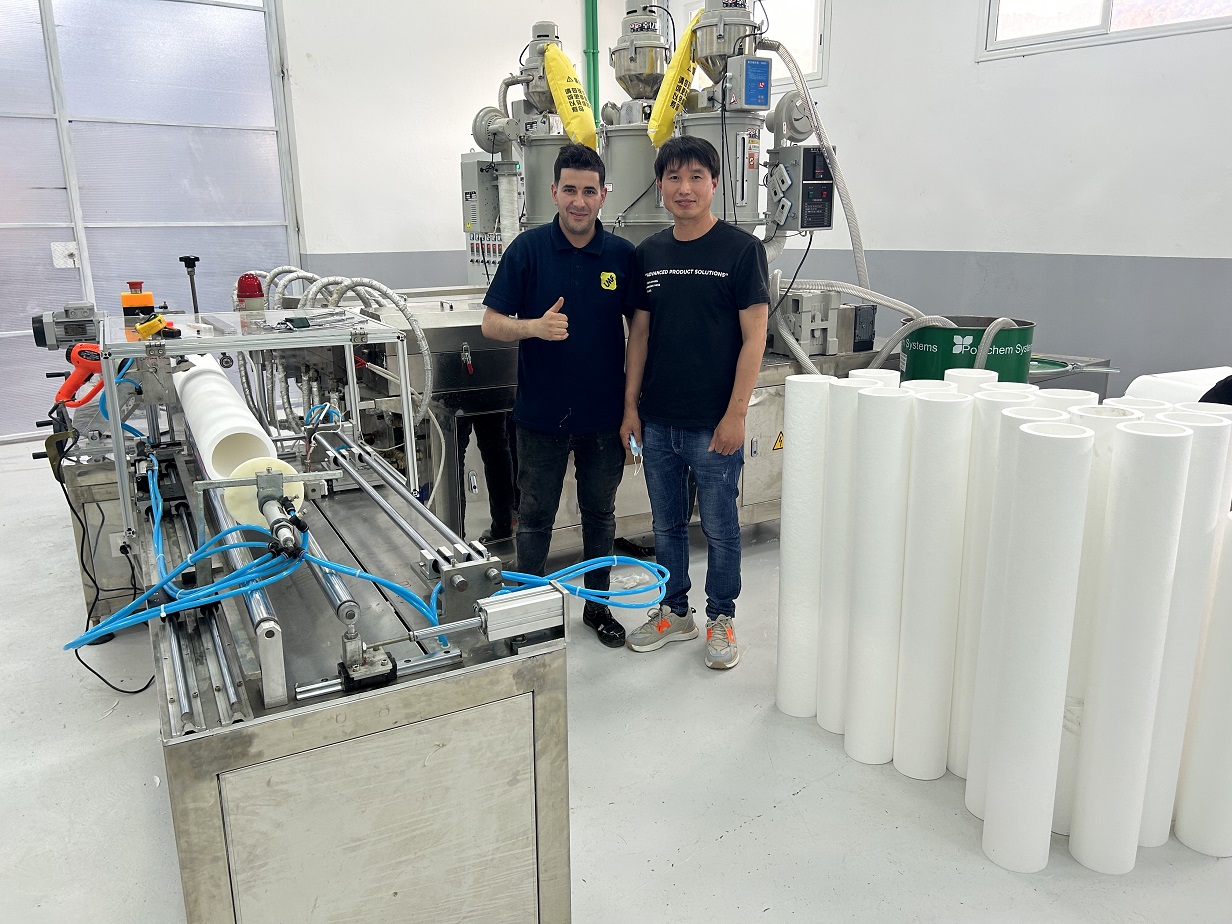

Our good service starts from your quote. If you have any questions about spun filter cartridge manufacturing machine, our customer center will get back to you within 24 hours. We have experienced sellers and engineer to fully understand your needs and design your filter cartridge making machine or filler element production line. More importantly, if you need technical help, our engineers could teach you online or visit your factory to install filter cartridge making machine.

More Application

Our spun filter making machines have high filtration accuracy, widely used in the pre-treatment of purified water, circulating cooling water, drinking water, laboratory water, boiler water, oilfield water injection. They are suitable for many industries such as pharmaceuticals, electroplating, printing, painting, color expansion, fuel oil, and beverages. We can help you build a convenient and fast filter element production line, with long service life, high output, and lower costs.

Custom Solution

As a professional spun filter making machine manufacturer with 35 years of experience , we have established sales center, design center, research center, production base and customer service centers. We boast 6000 square meter factory to ensure on-time delivery. According to your specific requrement, we are able to provide one-stop spun filter cartridge manufacturing solution from design to production line.

Yes, we provide a warranty for our spun filter making machines. The warranty period varies depending on the specific machines. Please contact us for detailed information on the warranty terms for each type.

The MOQ is generally 1 unit, but it may vary depending on the specific machine and custom requirements. You can contact us for more details.

Our lead time is typically around 15-30 work days. For a more accurate timeframe, please contact us. If you require an expedited timeline, we will consider your request and do our best to accommodate your needs.

Our machines are designed to produce a variety of filter cartridges, including spun-bonded and melt-blown types, suitable for water filtration, air purification, and industrial use.

Our machines are compatible with a range of materials, including polypropylene (PP), polyester (PE), and cellulose, allowing for versatility in the types of cartridges produced.

Yes, we offer customization options to meet your specific needs, including modifications for different filter sizes, production speeds, and additional features like automated quality control.

Yes, we offer comprehensive training programs for your staff, both on-site and online, to ensure they are proficient in operating and maintaining the filter cartridge making machine.

Here is a description of the news details.Here is a description of the news details.

Here is a description of the news details.Here is a description of the news details.

Get in touch with us